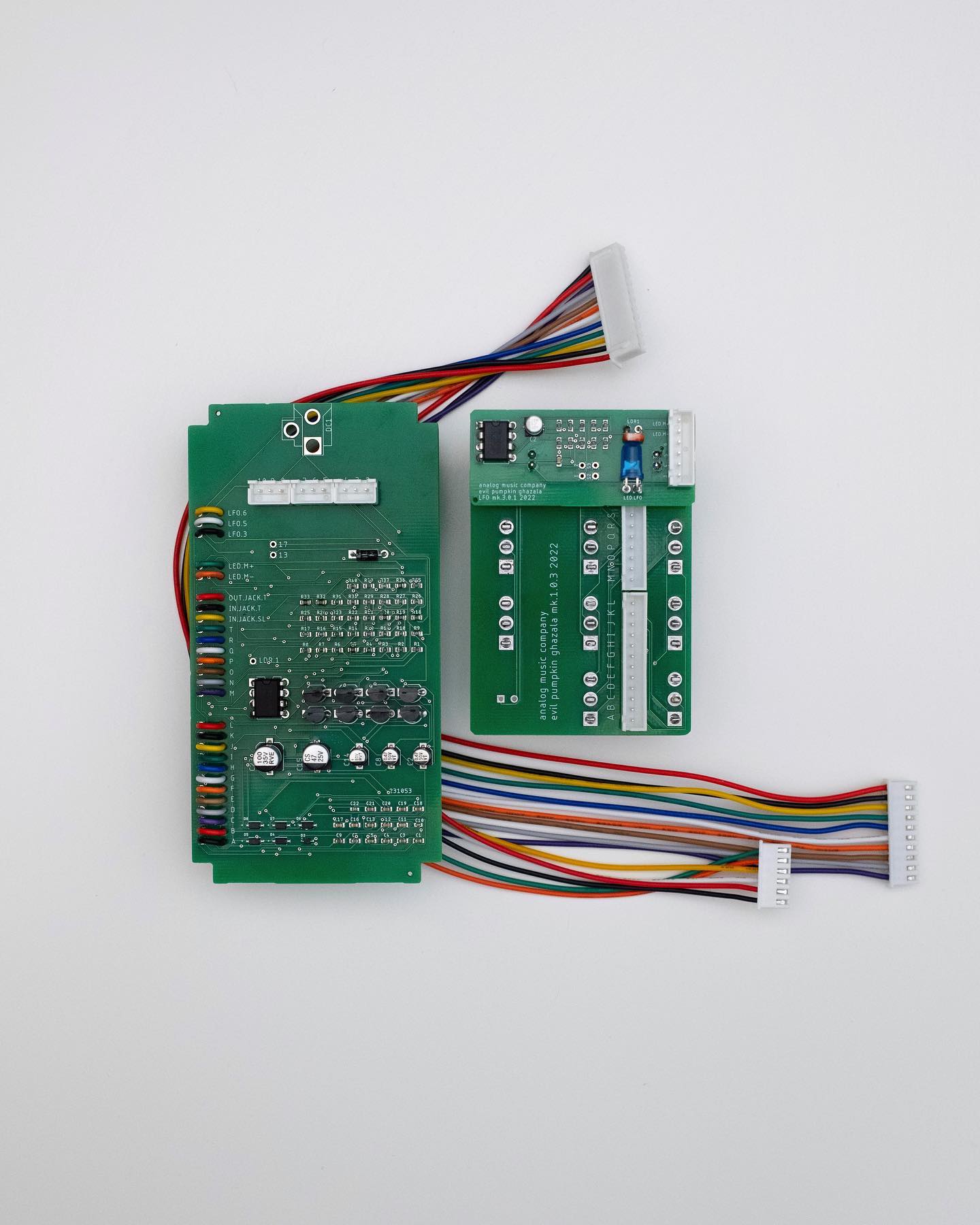

Big update: The Evil Pumpkin is completely in house.

Since the first day of the Evil Pumpkin project I knew this step would be inevitable if we wanted this product to be sustainable. The tie to the older through hole component DS-1 units (a new SMD DS-1 cannot be modded the way we need it) though may seem to be a no big deal - there are millions of DS-1s and most likely they will never run out of stock) - has a lot flaws in reality. We had to break it. And though producing our own boards instead of utilising the Boss ones inevitably means the additional cost (boards + components) and kind of a departure from the very first units, there are quite a few strong reasons why we started using our own PCBs in the Evil Pumpkin.

So why it is important:

1. The build from an existing DS-1 is hugely time and energy consuming - one Ghazala takes up to 3 days of work with huge amount of time being spent to disassemble and desolder the components of the old board, debug the circuit in case some mods have been done to it, drill, solder all the wires and reassemble. I need to literally sit alone in the absolute silence for some time after I complete the pedal - such high the level of exhaustion is. It can not be done on the regular basis physically and mentally. While the in house PCBs let me concentrate on building instead of debugging or reversing somebody’s previous mod, it saves time, energy and is a very rewarding experience.

2. Mods, mods, mods. While the Evil Pumpkin Ghazala is also a mod, but not all mods are equal. In most cases home-modded units are the real pain. It is virtually impossible to tell if the pedal was modded or not while buying online so every time it is a lottery. From the clipped legs on diodes to some funky replacement parts and sloppy soldering. It increases the risk of the unite failure in the future, it makes the behaviour of the pedal unpredictable, they all sound and react to our mod a little bit different either. Troubleshooting a home modded circuit and replacing the parts needs even more time and it affects the whole operation. So by using our own PCBs we are completely eliminating this issue.

3. Robustness. What makes Evil Pumpkin different is that it is in fact a product of several builders divided by 20 or more years in time. And the pedal built in such a way is exposed twice as much as a freshly built unit. The risk of failure of the component or a solder joint which is 30 years old is quite high and I really don’t want to expose our pedal like that.

4. Older DS-1s are becoming more expensive and harder to find. Component through hole Boss pedals are very popular among people making mods. They are not produced anymore and though you can still source 30-50 pedals it is getting much more expensive (DS-1s used to cost us USD 30 shipped two years ago. Now we are getting them at USD 50 shipped). Also it is more complicated to source a significant quantity of the pedals within the reasonable timeframes since they are not that widely available.

5. We have much more flexibility now. There will be builds with different transistors and different integrated circuits. I want a JRC4558 variation, RC4559P, TL072, LM308N, LM1458 variation, a NOS soviet opamp variation or even a double opamp - now it is all possible. Trying an older circuit variation is also tempting. Only our imagination is the limit - which is the core idea of the whole Evil Pumpkin project.

6. The build is far superior, much cleaner and robust and service friendly. I am not afraid anymore that some old solder joint of the original DS-1 might fail and we will have to disassemble and debug the whole Evil Pumpkin. Firstly, everything is minty fresh inside the pedal and secondly the construction is very solid and ready for years of abuse. I think that mechanical components will be the first to be replaced due to yearly wear and tear but the internals will work as intended.

7. We will be able to develop the Evil Pumpkin further. There are couple things I have in my mind for the coming updates. They were not possible to implement with the Boss PCB, but now we are free to do what we want.

8. Warranty repairs and turnarounds: In case something fails on the Evil Pumpkin we will be able to repair it with very short turnaround time. Servicing was one of my biggest concerns as the number of Pumpkins grows. With the Boss PCB it could take days to detect the issue. With our new PCBs it can be done within hours including disassembly and reassembly of the unit.

To conclude I can’t even express how happy I am that we have taken this step which is life changing for AMC as a company and me personally. It unleashes the my creativity and allows to invest my time and energy into the development of the Evil Pumpkin further a fear that tomorrow we will not be able to source the old DS-1s, the old components or solder joints will start failing and we will drown in repair work.

The Evil Pumpkin is finally free its Achilles heel. It took us 3 years, but we have made it!